Research

MEMS Deformable Mirror for Adaptive Optics

Project Overview

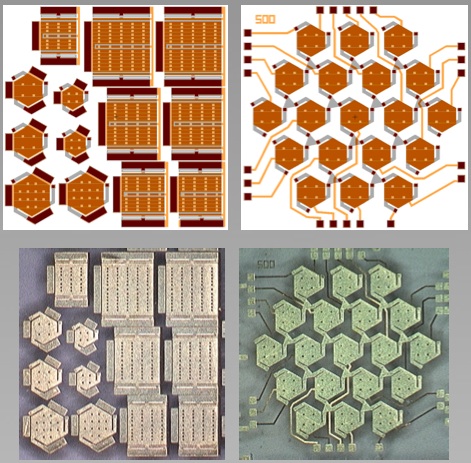

High ascpect ratio process can enable the fabrication of 3-dimensional Micro-Electro-Mechanical System (MEMS) deformable mirrors with large-stroke (>10um), higher packing density and at lower cost than currently available technology as are required for use in future adaptive optics systems in astronomy and visions science. Diffferent actuators designs, materials and post-processing prodcedures fabricated in a high-ascept ratio process that allow large vertical heights of up to 1mm have been investigated.

MEMS Deformable Mirror designs.

MEMS Deformable Mirror designs.

Various types of large-stroke actuators were simulated individually and as part of a mirror system consisting of actuators bonded to face plates with different boundary conditions. Simulation results along with measurements of the displacement of the actuators utilizing a white-light interferometer have shown the ability of the actuators to achieve a displacement of 1/3 of the gap between the spring layer and counter electrode.

The printing process is directly scalable by adding additional desktop printers or by using higher productivity printers. Higher productivity printing systems are shown in the figure below. Once a process has been developed on a lower speed printer it can be directly transferred to a higher speed printer for increased throughput without any additional process development.